Turbocharging has been a game-changer in automotive technologies, enhancing the performance and efficiency of engines. As you might have heard, introducing a turbocharger in diesel engines is a good way to boost your diesel engine, but what does this mean exactly? Let's find out how can a turbocharger in a diesel engine help car performance.

This article explores turbochargers' current prevalence and necessity in modern engines. It dives into their history and functionality and offers insight into the different types of turbochargers.

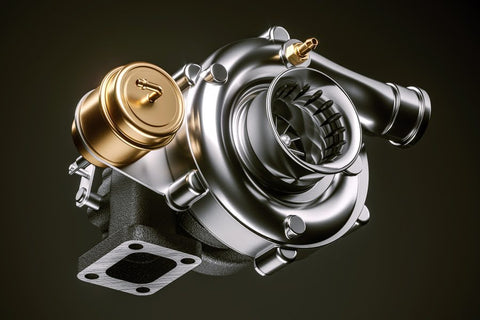

Source: shutterstock.com / Photo Contributor: KsanderDN

Turbocharger in Diesel Engine

Turbochargers have been boosting diesel engines for decades, significantly improving their power and efficiency. The concept of using exhaust gases to drive a turbine, which then compresses air into the engine, revolutionized diesel engine performance. It was first introduced during the early 20th century, with the initial turbocharging system offering a power increase of only 40%.

During 1920, turbochargers were still under development, with material limitations hindering their performance and applicability. Also, technological advancements during World War II helped overcome certain challenges. In the 1950s, the first lineup of turbocharged diesel vehicles was issued by Volvo and MAN.

Today, the turbo situation in the automotive industry has largely shifted. This allowed turbo-powered engines to become a commodity rather than an occasional sight.

Do all diesel engines have turbos?

A diesel engine doesn't necessarily come with a turbocharger. However, most modern diesel engines in the US market include one. Modern passenger cars on the US market coming from brands such as Volkswagen, BMW, Mercedes-Benz, and Porsche feature are more likely to feature a turbocharger.

Yet, turbo-powered diesel engines are likely a rarer sight in developing countries. Still, trends reveal that turbocharging is becoming a standard for most global automakers.

Why do diesels need turbos?

Some of the main issues that led to turbocharging the majority of today's diesel engines include stricter emission regulations, the need for more horsepower, and a better response. We will look into their work process to better explain the advantages of turbochargers in diesel engines. So, how does a turbo work on a diesel engine?

In diesel engines, the combustion process starts when fuel is injected into the engine; hence, comes the name direct injection. You will also find that diesel engines are also called compression-ignition engines.

In a nutshell, diesel engines combine fuel and air with ignition based on heat and pressure. As owners of diesel engine vehicles may tell you, these engines can operate on various air-fuel ratios.

However, having a lower RPM (revolutions per minute), diesel engines have less time to burn fuel and produce power. This is where turbochargers make their entrance.

Turbochargers are exhaust-driven compressors that can introduce more air into the engine while eliminating the need for a higher RPM. Simply put, by compressing more air into the combustion chamber, turbochargers allow more fuel to be burned, resulting in increased power output.

Environmentally friendly

As we mentioned, increased power is not the only turbocharger function in diesel engines. Turbochargers also help reduce emissions, making diesel engines more eco-friendly.

Enhancing fuel oxygenation through turbocharger design promotes increased combustion. Why does this matter? Full combustion of hydrocarbons in fossil fuels like diesel results only in carbon dioxide and water.

In contrast, incomplete combustion releases fossil fuels and other toxic elements into the atmosphere. By adding more air into the engine, turbochargers help accelerate combustion contributing to less toxic particles being released in the environment.

Types of Turbochargers for Diesel Engines

Several types of turbochargers for sale are available for diesel engines, including wastegate and variable-geometry turbochargers. Each type has its own set of pros and cons. So, we have explained them briefly:

Wastegate turbochargers

Wastage turbochargers use a wastage valve to regulate the turbo's performance and boost pressure. These turbos are best known for controlling turbo speed and protecting the engine from damage associated with over-boosting. They achieve this by diverting some exhaust gasses away from the turbine wheel.

Wastage turbos can be either internally or externally gated. Internally gated types are more compact, while externally gated designs are better suited for boat control and efficiency.

Variable-geometry turbochargers

Variable-geometry turbos (VTGs) feature aerodynamically shaped vanes within their turbine housing. These vanes alter the turbo's area-to-radius ratio to match the engine RPM.

When used in engines with a higher RPM, the ratio increases, allowing for an improved airflow. In low RPM engines, this turbocharger spools faster, enhancing gas velocity. VTGs are mainly preferred due to their reduced turbo lag effect and smooth torque band.

Source: shutterstock.com / Photo Contributor: tsyklon

Conclusion

Turbochargers have become integral to modern diesel engines, offering significant benefits for power, efficiency, and environmental friendliness. Turbochargers have continually evolved from their inception in the early 20th century to becoming a near-standard feature today.

These advancements help modern manufacturers ensure that turbochargers meet the need for more power and adhere to stricter emission regulations. The turbocharger in diesel engines, thus, symbolizes a commitment to innovation and sustainability in automotive technology.