The fuel pump delivers a pressurized fuel flow from the gas tank to the engine. The fuel pressure needs to be consistent for the engine to work smoothly, as variations in pressure can lead to performance issues and damage. But what are the fuel pump pressure specs?

Fuel pump pressure is an important figure for the engine’s performance and longevity as it helps unleash the vehicle’s full potential and avoid certain performance-related issues.

So, we will focus on the pressure specifications of fuel pumps and explain how they impact the engine’s work.

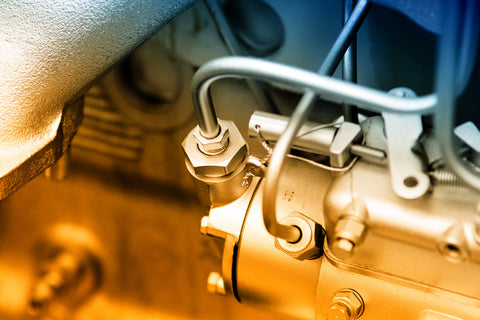

Source: shutterstock.com/ Photo Contributor: Budimir Jevtic

Fuel Pump Pressure Specs

Fuel pump specifications vary according to the engine type. For example, gasoline engines have different fuel pressure requirements than diesel engines. Also, the fuel pressure specifications may vary from vehicle to vehicle, even if they share the same engine type.

Having an accurate fuel pressure is critical for proper atomization and, consequently, combustion. These two processes in the engine create a controlled explosion in the combustion chamber, which drives the pistons and ultimately moves the vehicle forward.

Every so often, the time comes to replace your fuel injection pump. With us, you can find a trusted partner that delivers the ideal solution to match your car’s needs and your budget. Whether it’s a new or remanufactured fuel injection pump, here at Goldfarb & Associates, we’ve got it all as we strive to become our customers’ reliable source of premium quality parts.

So, here are the fuel pump pressure variations depending on the engine type:

Fuel injection pressure in gasoline engines

Gasoline engines require a specific range of fuel pressure for optimal performance. This range can vary depending on the make and model of the vehicles, but for most gasoline cars, fuel pressure falls within the range of 30 to 50 PSI. High-performance gasoline engines might require higher fuel pressure, which can go up to 60 PSI or more.

Gasoline engines can utilize two types of fuel injection systems: direct and port injection. Direct injection systems deliver fuel at significantly higher pressures, which is necessary to create the fine fuel mist required for achieving efficient combustion. Conversely, port injection systems deliver the fuel upstream of the intake valve and usually operate at lower pressures.

Fuel injection pressure in diesel engines

Diesel engines have specific fuel pressure requirements because they operate on a different principle than gasoline engines. They need a considerably higher fuel pressure because it’s necessary to compress the air-fuel mixture and achieve ignition through compression, which is specific for diesel engines.

Furthermore, diesel engines rely on precise fuel injection timing to achieve the required power output. High-pressure fuel injection systems can deliver fuel with great accuracy, with the latter versions achieving intervals as short as 1 microsecond.

Many diesel engines use a standard rail injection system, which maintains constant pressure in a shared fuel rail. The high fuel injection pressure in diesel engines contributes to their reputation for power and efficiency. It allows for better atomization and more even fuel distribution to the combustion chamber, ultimately leading to high performance.

Variations in fuel pressure by vehicle

Some vehicles use naturally aspirated engines, while others have turbochargers or superchargers. These variations can have a significant impact on the required fuel pump pressure specs.

Turbocharged engines require higher fuel pressure to accommodate the increased air intake and achieve timely and effective combustion. Supercharged engines also have specific pressure requirements as they create a boost pressure and require larger fuel injectors to deliver the required fuel. However, aspirated engines rely solely on atmospheric pressure to draw air into the combustion chamber.

The compression ratio of an engine also affects the fuel pressure requirements, with engines with a higher compression ratio demanding higher fuel pressure. Modern vehicles have advanced fuel systems with direct injection technology, while older vehicles may require lower fuel pressures.

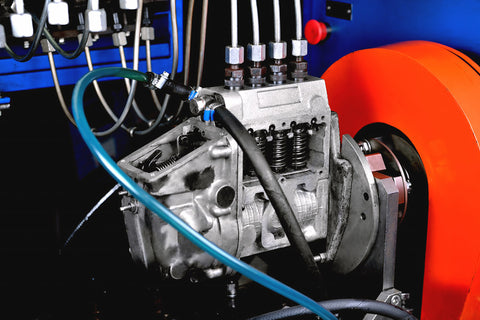

Source: shutterstock.com/ Photo Contributor: Aleksandr178

Diagnosing Fuel Pump Pressure Issues

To maintain a well-functioning engine, you must have some level of knowledge and understanding to recognize the symptoms that emerge. When there are issues with the fuel injection pump, the engine’s performance and efficiency will likely become compromised, so promptly addressing the problems may save you a lot of trouble and expenses.

Here’s how to notice that there’s something wrong with the fuel pump pressure specs:

High fuel pressure symptoms

- Excessive fuel consumption

- Black smoke from the exhaust

- Engine knocking

- Worsened engine performance

Low fuel pressure symptoms

- Engine stalling

- Hard starting

- Poor acceleration

- Misfiring

- Worsened performance

How to Measure the Fuel Pressure

Fuel pressure gauges help determine if there are any issues with the fuel pressure. This device connects to the fuel rail or test port to measure the fuel pressure. The findings are compared to the manufacturer's specifications for the vehicle.

Therefore, abnormal readings, whether higher or lower pressure than the recommended level, can indicate issues with the fuel pump, fuel filter, or pressure regulator.

Fuel injector pressure calculator

There is a formula to determine the required fuel injector size or flow rate for a specific engine. It’s based on factors such as engine type, horsepower, and the desired air-to-fuel ratio. It helps calculate the correct amount of fuel that the injectors deliver to the combustion chamber.

The engine’s horsepower is multiplied by the amount of fuel it needs to create that power. Then, that number gets divided by the total number of fuel injectors in the engine and is divided again by the pressure difference that pushes the fuel into the engine.

The result of this calculation gives the required flow rate for each fuel injector, which means that each injector must be able to deliver this amount to satisfy the engine’s power needs.

Common issues

These can be small-scale issues; fixing them is relatively easy if you have the necessary know-how. Sometimes, it can be about disconnected wiring or replacing a component such as the filter or the regulator. If everything fails, then the pump itself may be at fault, and you may need professional assistance. However, some of the common problems might be the following:

- The pump may not be receiving the correct voltage, or it may not have a solid ground connection.

- Clogged fuel filter

- Malfunctioning pressure regulator

- Faulty fuel pump relay

- Blown fuse

Maintenance of the Fuel System

The fuel system needs to be cared for properly to maintain its proper function and durability. You must perform frequent visual inspections of the fuel system components and look for signs of wear, leaks, or other damage.

Replacing the fuel filter according to the manufacturer’s recommendations is important because a clogged filter can block the fuel flow and place extra stress on the fuel pump. Plus, always use high-quality fuel because contaminated fuel can lead to fuel system problems, and use additives to clean and prevent the buildup of deposits.

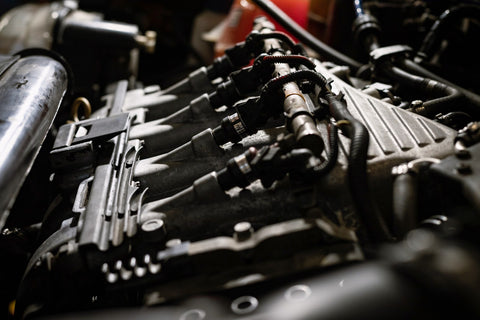

Source: shutterstock.com/ Photo Contributor: Skatty

Conclusion

We discussed the role of fuel pumps and fuel pump pressure specs as key elements in achieving optimal engine performance. We also covered the basics of fuel pumps, the importance of maintaining correct fuel pressure, variations in fuel pressure by engine type, and the methods to diagnose issues with the fuel pump.

Altogether, you learned how to measure your vehicle’s fuel pressure and how to calculate the necessary amount of pressure with the fuel injector pressure calculator formula. Remember, if you require some high-quality diesel parts, you can always reach out to us!