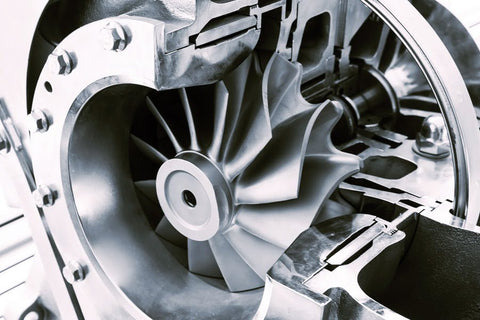

In the realm of automotive performance, the turbocharger stands as a pivotal innovation, significantly enhancing the power output of an engine. Central to this system is the turbocharger turbine, a component that plays a crucial role in harnessing exhaust gases to boost engine efficiency and power.

This article highlights the turbine's function and importance as a crucial component and critical to the turbocharger's performance.

Source: shutterstock.com / Photo Contributor: Evannovostro

Types of Turbocharger Turbines

Turbocharger turbines come in various designs, each with its unique advantages and limitations. Each type of turbine has its specific application, with the choice depending on factors like engine size, desired performance, and space constraints.

Radial turbine

Radial flow turbines operate with the working fluid flowing radially relative to the shaft. They are crucial in turbochargers for their ability to handle high-pressure ratios per stage and their sustainability in low to moderate power ranges. Compared to axial turbines, these make a simpler, more durable choice and can be more efficient for certain power ranges. However, due to their heavier rotors, radial turbines are not the best choice in high-power applications (above 5MW).

Axial turbine

Axial flow turbines have fluid flowing parallel to the turbine's axis. This design is widely used in stem and gas turbines. In turbochargers, they operate by converting exhaust gas energy into rotational energy, which is then used to compress the intake air. Their design allows for a more direct flow path, offering high energy conversion efficiency.

While radial turbines might be more efficient in certain power ranges due to their simpler design, axial turbines can handle higher flow rates more efficiently. However, axial turbines may come with some mechanical and thermal stress limitations.

Mixed-flow turbine

Mixed-flow turbines (MFTs) are a hybrid of radial and axial turbines and merge the characteristics of both designs. The best way to explain the inlet flow in mixed-flow turbines is to say that the angle is somewhere between the radial and axial design. In these turbines, the fluid enters radically and exits axially.

Their design offers better efficiency and performance across a broader range of conditions. For instance, this type of turbine reduces the formation of secondary flow, which is an issue commonly associated with radial turbines.

Mixed-flow turbines are usually used in vehicles where the engine speed and load vary significantly. A study investigating mixed-flow turbines suggests that these turbines have improved performance at low blade speeds. Meaning they can utilize a good amount of the energy available in exhaust gas.

While this type of turbine offers better efficiency and performance across a broader range of conditions, their complexity sometimes gets in the way.

Turbocharger Turbine Components

The turbine of the turbos for sale consists of several key components:

Turbine wheel

The turbine wheel is the part of this system that drives the compressor. It achieves this using exhaust energy. The turbine wheel's design must follow the set compressor's design within the turbocharger. It's worth noting that to keep up with the set compressor mass flow, turbine wheels in turbochargers usually come with a flow of around 1.03 times that of one of the compressors.

Turbine housing

The turbine housing is used to connect the turbo to the engine. Being one of the core components of the turbocharger, the turbine housing is available in two types: open and divided.

The divided turbine housing separates the exhaust path from the turbine wheel using a divider. In turn, this allows the turbine to transmit higher energy. Such turbine housings are mainly preferred for low-speed turbos that feature a lower RPM. In contrast, the open turbine housing is preferred for engines with a higher RPM.

Turbine shaft

The main purpose of the turbine shaft is to hold the compressor and the turbine wheel together. However, this turbine component also increases the air pressure intake within the combustion engine. The typical appeal of a turbine shaft usually features a threaded structure, creating a smoother appearance; however, some shaft models may also hold rougher cut threads.

Factors That Affect Turbocharger Turbine Performance

Some of the factors that can influence the performance of turbocharger turbines include the following:

Turbine wheel size

The size of the turbine wheel is directly linked to an engine's efficiency. Turbine wheel size plays a significant role in lag. Smaller turbine wheels come with reduced inertia and offer less lag, while larger sizes introduce more interior and, therefore, come with a slower response. Still, we should also note that larger turbine wheels feature greater exhaust gas flow while also increasing pressure.

Turbine design

A study investigating how turbine design impacts engine performance suggests that turbocharger turbine design plays an important role in turbocharger efficiency. Although this study was based on simulation, its findings highlight the significance of the turbine diameter ratio and call for a more contemporary mixed-flow design to ensure better turbocharger performance.

Source: shutterstock.com / Photo Contributor: Palitsyn Evgenii

Conclusion

Turbocharged turbines support converting exhaust gas energy into increased power, making them crucial in enhancing automotive engine performance. Going through the different types of turbines, we can say that each one has its unique advantages.

For instance, radial turbines are favored for moderate power ranges, while an axial turbocharger turbine excels in high flow rates. On the other hand, mixed-flow turbines, being hybrid, have a wider applicability range but a more complex functionality.

While a balanced turbine design will likely work best in modern turbochargers, factors such as wheel size may dictate its function and influence the overall performance of the turbocharger.