The diesel injection system is the driving force of your vehicle, ensuring a timely fuel delivery to the combustion chamber. The way it works and its efficiency directly impact the fuel quality and functioning of your car. So, how does a diesel injection pump work, and what exactly does it do?

Below, we’ll go into detail about the fuel supply process and provide tips for proper maintenance of your diesel injector.

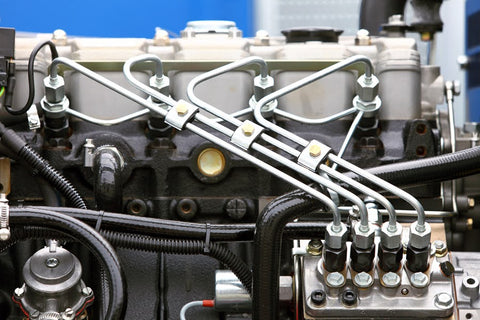

Source: shutterstock.com / Photo Contributor: Matveev Aleksandr

How Does a Diesel Injection Pump Work?

What is a diesel pump? A diesel pump is a device that sends pressurized fuel to the combustion chamber through different components in the engine. However, the process itself is a bit more complicated.

So, how does a diesel injection pump work? Here’s a quick rundown of the process:

- Fuel is drawn from the fuel tank through a fuel filter to eliminate impurities.

- The filtered fuel is pressurized by the lift pump and sent to the diesel injection pump.

- The diesel injection pump boosts the pressure to an even higher level and delivers high-pressure fuel to the injectors. It is synchronized with the crankshaft to ensure a timed delivery of fuel to the cylinders.

- Once the fuel is in the cylinders, it goes to the cylinder-specific injectors, which spray it into the combustion chamber.

The injection pump plays a vital role in fuel injection, ensuring precise fuel delivery to the injectors and boosting the vehicle's efficiency.

The Role of Fuel Injection Systems

The main purpose of a fuel injection system is to deliver fuel into the engine cylinders through a diesel fuel injection pump. The precise delivery of fuel promotes better combustion, improving your vehicle's fuel economy and reducing emissions. Unlike a carbureted system, an injection system delivers a superior air-to-fuel ratio, making it the obvious choice for gearheads.

Evolution of fuel injection technology

The history of fuel injection systems dates back to 1891 when the British Herbert-Akroyd oil engine was introduced as the first with a pressurized fuel injection system. It used a jerk pump to deliver fuel to the combustion chamber at high pressure. This invention marked the beginning of direct injection, and in 1924, MAN Truck & Bus announced the first direct-injected diesel engine for trucks.

As technology advanced, electronic fuel injection emerged as a novel fuel delivery system with enhanced electronic capabilities and improved fuel efficiency. From that moment, it was all about updating fuel injection technology and integrating more features to reduce pollutants and optimize fuel injection for various driving conditions.

Types of fuel injection systems

How does injection pump work on a diesel? To answer this precisely, you must be aware of the types of fuel injection systems:

- Single-point fuel injection – Also known as throttle body injection, SPI injects fuel into the throttle body, where the fuel is mixed with air and then delivered to the cylinders. It’s a straightforward system with a single distribution point, so it can also prove less efficient than the following injection type.

- Multi-point fuel injection – Also referred to as “port fuel injection”, MPI sprays fuel into the intake ports of the cylinders. The distribution is more even with this method, providing better air-fuel ratio control. It can regulate the fuel supply to individual cylinders for better combustion.

- Sequential fuel injection – This is a variation of MPI and works on the same principle, the only difference being that it injects fuel into the cylinders in varying sequences synchronized with the engine’s firing order. It’s a new-and-improved version of MPI, meaning it delivers double the fuel efficiency.

Types of Diesel Injection Pump Technologies

Older vehicles used mechanical injection pumps, which were later replaced with electronic ones. These types of pumps use a mechanical fuel system with cams and levers to control fuel injection.

The mechanical fuel system features a cam mechanism with a camshaft linked to the crankshaft. It activates fuel injectors according to the preset injection timing and opens and closes the intake and exhaust valves for optimal air delivery to the combustion chamber.

Most vehicles nowadays use electronically controlled injection pumps with an electronic control unit (ECU) and sensors controlling fuel delivery. The ECU manages the electrical systems in the engine, dictating how and when they operate.

Electronic injection pump technologies are superior to mechanical ones because they use a simplified fuel generation process, boosting fuel economy. Their price tag makes sense when looking at the advantages they bring to your vehicle.

Maintenance and Troubleshooting

To ensure your diesel injection pump lasts, you must maintain it properly. Here are some tips to help you take care of the injection pump and keep it in good condition:

- Check the parts of injection pump every once in a while – If you believe there’s a problem with your diesel injection pump, it could be that it’s clogged or lacking lubrication. You may also encounter electrical problems from loose or rusted connectors. You can easily solve these issues using a multimeter.

- Change the fuel filters – You should change your fuel filters after approximately 60,000 miles. However, you should consult an expert regarding your vehicle model and driving preferences for a specific answer.

- Use high-quality diesel fuel – Low-quality fuel can negatively affect the injection pump and cause premature wear and tear. On the other hand, premium diesel fuel has additives that purify the fuel, resulting in better fuel stability.

Source: shutterstock.com / Photo Contributor: Voyagerix

Conclusion

How does a diesel injection pump work, and why is it important? The injection pump is crucial because it pressurizes the filtered fuel, providing a smooth driving experience. The fuel is sent to the injection pump through the lift pump and then to the cylinders and injectors to power the combustion chamber.

This process varies depending on the fuel injection system of your vehicle. Some cars have a mechanical system, while others are more advanced and use an electronic one with fewer components and more accurate pressure regulation.

However, a modern fuel injection system alone doesn’t ensure optimal performance. Regular maintenance and repairs of the fuel pump are a must if you want to take advantage of the full capacity of your engine.