The diesel engine market is growing steadily, and its market value is expected to reach $78.8 billion by 2028. As always, diesel engines provide better drive than gasoline, which explains the growth in the market. Many diesel engine owners rely on either the inline or rotary pump. Both are robust and effective, but of course, there is a difference between inline and rotary fuel injection pump that splits the opinion of the audience.

In this article, we will study each pump in detail to see what is the difference between inline and rotary fuel injection pumps and discuss the pros and cons of each pump to help you decide which is better rotary pump or inline pump. Therefore, read on to find out more.

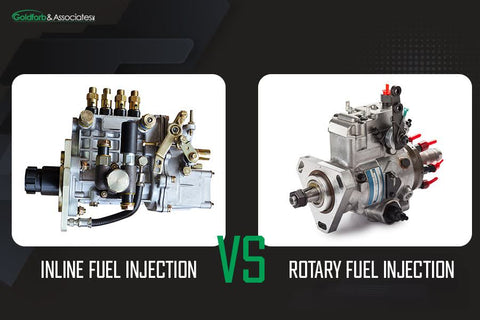

What Is the Main Difference Between Inline and Rotary Fuel Injection Pump

The fuel injection pump is the main component of the diesel engine. Its role is to deliver fuel to the engine to keep it running smoothly. Also, the fuel needed to reach a certain power depends on the fuel injection pump you'll choose. The inline injection pump and distributor injection pump are the most preferred ones.

The main difference between inline and rotary fuel injection pump is the method of distributing the fuel to the engine. Rotary pumps have a circular method of delivering the fuel to the engine, while the inline pumps operate in a linear method.

We discuss the differences between these two pumps in more detail below.

Inline injection pump explained

The design of the inline injection pump diesel is a kind of compilation. It’s created by a separate pump and plunger units connected inline per cylinder. As they are activated by a cam, they are fixed to the engine.

These pumps are known for delivering fuel to the engine at the correct time with the correct amount. To do so, injection pumps use a plunger and barrel to create the high pressure needed to fuel the engine. The plunger creates a pressure wave just enough to drive the fuel through a small chamber and then to the engine.

Injection pumps have mechanical and electric controls to deliver the fuel into the engine promptly, safely, and efficiently. They are super durable and sustainable assets for your engine.

For example, the Bosch A Injection Pump has a lifespan of half a million to a million range. With regular service and maintenance, you wouldn’t have to replace the pump for decades.

Source: shutterstock.com / Photo Contributor: Voyagerix

Rotary pump diesel fuel injection

The rotary fuel injection pump has a simple operational system. It delivers the fuel to the engine by pressure. Because of the high pressure, the fuel gets into the small chamber before it reaches the engine.

What’s typical about the rotary pump is that inside the pump, there is a rotor that spins at high speed, hence the name. The rotor creates the above mentioned pressure that’s needed for delivering the fuel inside the chamber. Otherwise, the rotor has several lobes that help with compressing the fuel into the pump. So, this is the main difference between a rotary inline and a rotary fuel injection pump.

These pumps are some of the best additions for a diesel engine as they are durable and effective, allowing improved performance and fuel efficiency.

Pros and Cons of Inline and Rotary Fuel Injection Pumps

To help you understand the difference between inline and rotary fuel injection pump, the following pros and cons of each pump compare the main features of each pump.

Pros and cons of inline injection pump

|

Pros |

Cons |

|

Traditional and tested pumps for vehicles |

No throttle control |

|

Cost-effective option |

Difficult start |

|

Easy to manage |

Pros and cons of rotary injection pump

|

Pros |

Cons |

|

Replaceable |

Low power |

|

Preciseness in delivering the right amount of fuel to the engine |

Fuel in the oil |

|

Injection pumps are mounted outside the tank, which allows you easy access |

Which Is Better Rotary Pump or Inline Pump?

Overall, rotary pumps are preferred because they are best known on the market. They are reliable, and they change the timing with intervention. On the other hand, the inline pumps have a better torque curve, and they pump fuel more easily and more effectively. Therefore, the choice is yours.

Inline pumps correspond with faster cars because of the precise fuel delivery into the engine. They have six barrels and plungers to put out more fuel efficiently compared to the rotary pump, which has only a barrel and plunger that does all fuel pumping. Therefore, you can imagine the comfort an inline pump provides. If you have a fast-to-luxury car or you often drive on highways, the inline pump will be more beneficial than the rotary.

But, if you don’t have a super fast car and you use it predominantly for daily activities, then you will only waste more money with the inline pump. The rotary pumps are super reliable and will serve you for ages.

Source: shutterstock.com / Photo Contributor: Dmitriev Mikhail

Conclusion

The main difference between inline and rotary fuel injection pump is the distribution system of the fuel to the engine. The inline fuel injection pumps have a linear system of distributing the fuel into the engine that works on high pressure. Additionally, the inline injection system is more recommended for high-performance diesel engines.

The rotary pump distributes the fuel to the engine through rotors that create circular motions. These pumps are most trusted as the rotary mechanism has existed on the market for a long time.

However, if you were to choose which is better rotary pump or inline pump depends on your purpose, car, and lifestyle.

Inline pumps are more associated with faster cars and high-performance engines. Rotary pumps go with average diesel engines.