We all recognize the signs of something wrong - smoke emanating from the exhaust, obnoxious engine noises, a sudden drop in oil pressure, and bad fuel efficiency. But rarely are we ready for the shock when the repair service tells us our engine is dead and needs to be replaced.

Wait! What?! You knew things didn’t look good, but you hoped the issues didn’t rise to the level of ‘dead engine’ bad. You love your truck, and that Cummins 5.9L Turbo Diesel under the hood was built to function about as reliably as they come. So much so that you’re not eager to toss it aside for a new one just yet.

Thankfully, you have other, less expensive options: you can purchase a remanufactured deluxe long engine block that has everything balanced and tuned and ready to drop into your engine bay, or you can get a rebuilt long block or short block, and modify it with new, remanufactured, or reused parts (that are still in good condition) from your existing engine.

Refurbished, Rebuilt, or Remanufactured?

Although many people use these terms interchangeably, they mean different things. A component sold as refurbished has been taken apart, cleaned, and had worn or damaged pieces replaced. The part is then put back together and sold.

Rebuilding also means stripping down an OEM component and replacing the worn and damaged parts. The main difference is that the replaced parts are tested and calibrated to original factory specifications, making the rebuilt product much more reliable than its refurbished counterpart.

Remanufacturing differs from rebuilding only in that the technician will replace all the components of a product and calibrate them to new specifications, not just the worn or damaged ones. Structurally and in terms of function and dependability, rebuilt and remanufactured parts are just as good, if not better, than OEM parts. For purposes of this article, we use rebuilt and remanufactured synonymously.

As a veteran diesel parts supplier, we know the value of high-quality, rebuilt components. Let’s take a look at some of the reasons we recommend using remanufactured parts to rebuild your diesel engine:

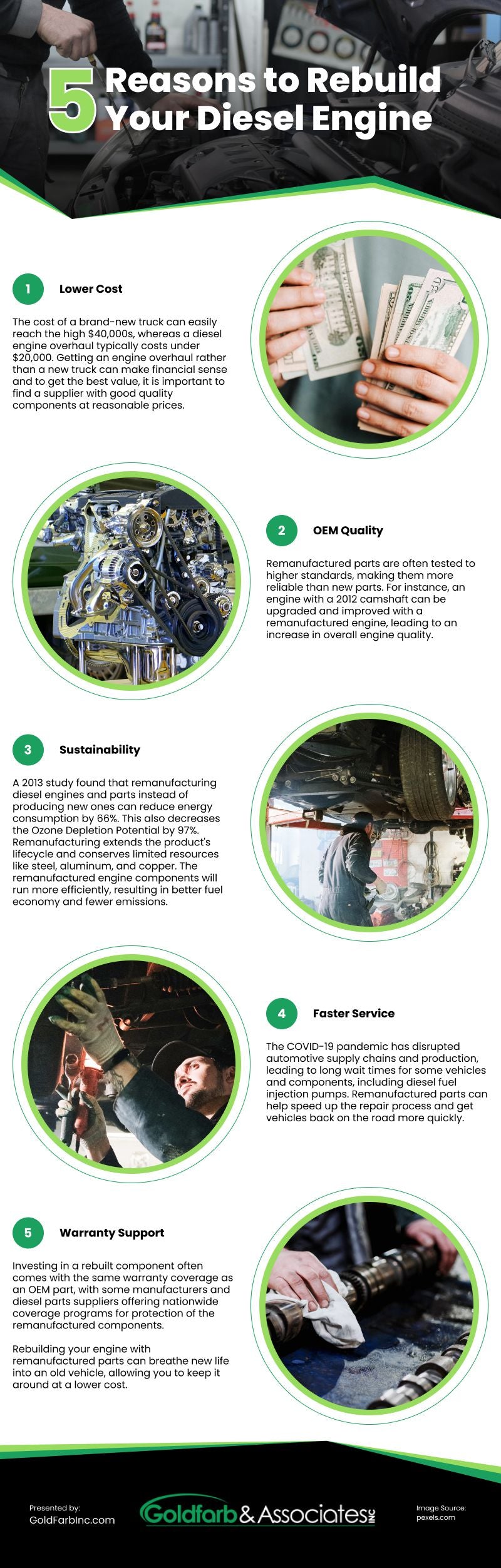

1. Lower Cost

The cost difference between buying a brand-new truck and doing an engine overhaul is staggering. A new truck off the lot will easily stretch your budget into the high $40,000s, and upgrades and modifications will cost you even more.

On the other hand, a diesel engine overhaul will generally cost under $20,000, depending on whether or not you have a professional to do the work, the tools and skills you have available, and the cost of your remanufactured parts. The engine quality will be consistent with that of a brand-new truck.

At the end of the day, taking out a small business loan for an engine overhaul instead of saddling yourself with a hefty monthly car payment for the next five years makes financial sense. To get the most bang for your buck, finding a supplier with a wide selection of components for rebuilt diesel engines that delivers excellent quality at reasonable prices is essential.

2. OEM Quality

In many cases, remanufactured parts are tested against higher-than-original specs, often making your rebuilt ‘old’ engine more robust and dependable than a new one. For example, if the camshaft in your truck dates back to 2012, this component has undoubtedly improved in the last decade. A remanufactured engine will integrate those upgrades into your system, effectively increasing engine quality across the board.

3. Sustainability

A 2013 Lifecycle Assessment Study found that remanufacturing diesel engines and parts instead of manufacturing new ones could reduce energy consumption by 66%. Of the environmental impacts assessed, the Ozone Depletion Potential decreased the most - by 97% - using remanufacturing processes.

In addition, lengthening a product’s lifecycle through remanufacturing dramatically reduces the number of raw materials needed to create new parts, conserving limited resources like steel, aluminum, and copper.

Finally, with your engine components rebuilt and re-tooled to meet or exceed original specs, your motor will run more efficiently, creating greater fuel economy and fewer harmful emissions. That’s good for you and the environment.

4. Faster Service

The global pandemic short-circuited automotive supply chains and imposed production restraints, and more than two years later, we’re still trying to recover. While more standard and super-duty diesel trucks are finding their way onto dealers’ lots, the wait times for some vehicles remain high - anywhere from a couple of months to a couple of years.

Many new components are in the same boat, which means you may have to wait months for something as simple as a diesel fuel injection pump. Buying remanufactured parts from diesel engine rebuilders will significantly speed up the repair process and get your vehicle up and running as quickly as possible.

5. ‘Best-In-Class’ Warranty Support

When investing in a rebuilt component, you often get the same warranty coverage as an OEM part. Depending on the manufacturer and who rebuilt the product, that can include everything from replacement costs to labor costs. Today, several manufacturers and diesel parts suppliers offer competitive nationwide coverage programs to protect your vehicle’s remanufactured components.

Nobody wants to junk a beloved vehicle, especially if everything but the engine continues to work as intended. If you find yourself in this unenviable position, consider rebuilding your engine with remanufactured parts. It will inject your old vehicle with new life and keep it around at a lower cost of ownership for years to come.

Infographic

Smoke coming from the exhaust, intrusive engine sounds, a rapid reduction in oil pressure, and poor fuel economy are all telltale symptoms of trouble that we can all easily identify. We understand the significance of high-quality, remanufactured parts as a seasoned diesel parts provider. Let's look at some of the factors in rebuilding your diesel engine with remanufactured components.