Now that winter has begun, it's more critical than ever to keep your trucks running despite the weather. Unfortunately, all that beautiful snow and ice can wreak havoc on your diesel engines, resulting in hard starts, gelled fuel, clogged fuel pumps, cracked belts, and dirty air filters.

Coupled with ongoing parts supply shortages and inflationary repair costs, you could be looking at lengthy delays and high price tags when something goes wrong with one or more of your trucks. And stalled vehicles translate into delayed deliveries and lost sales.

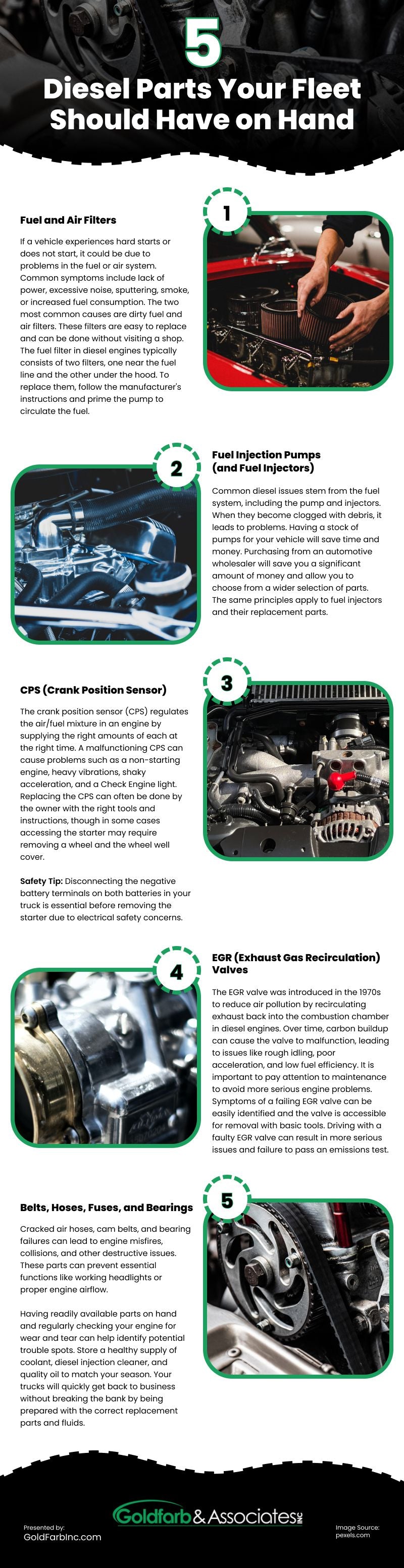

So how do you keep your fleet on the road? As a veteran diesel parts supplier, our technicians recommend that you always keep the following replacement components on hand:

1. Fuel and Air Filters

If your vehicle experiences continual hard starts or doesn't start at all, that usually points to problems within your fuel or air system. Other warning signs include lack of power, excessive noise, sputtering at high speeds, reduced RPMs, smoke, or increased fuel consumption. One of the most common fuel system issues is a dirty fuel filter.

A dirty air filter will cause your engine to exhibit many of the same symptoms, plus other issues, such as engine misfires, a strong smell of fuel in the cabin, or flame coming out of the exhaust pipe.

Thankfully, both filters are inexpensive and easy to keep on hand, and your drivers can quickly replace them without making a trip to the shop. Depending on your truck's engine, you will only need some basic tools to undo the fasteners that hold your air filter in place.

2. Fuel Injection Pumps (and Fuel Injectors)

As discussed above, you can trace many common diesel issues back to the fuel system, including the pump and injectors. Problems arise when either become plugged up with engine residue and other debris because of dirty fuel or filters.

Having a small stock of pumps designed for your vehicle will save you precious time when your fuel system fails and needs repairs. Showing up with your carefully-selected component means not wasting time hunting for the best deal or waiting for the shop to order it.

Diesel pump parts can also cost you thousands of dollars if you're forced to accept whatever your repair service has available. An automotive wholesaler likely will have fuel injection pumps for sale at a fraction of the price, so purchasing in advance will save you a bundle, and you'll be able to choose the item you want from a wider selection. The same principles apply to fuel injectors and fuel injector replacement parts, such as spray nozzles, solenoid cores, plunger and barrel assemblies, and glow plugs.

3. CPS (Crank Position Sensor)

Your CPS regulates the air/fuel mixture inside your engine to supply just the right amounts of each at the right time to create combustion. When that sensor isn't functioning correctly, it disrupts the timing of the mixture's delivery into the fuel injectors and throws off the engine's proper ratio of air to fuel. Several things can happen due to a bad crank sensor, including being stranded on the side of the road because your truck won't start, heavy vibrations, shaky acceleration, and the illumination of your Check Engine light.

Depending on your engine, you can often replace crank sensors yourself without too much trouble. The sensor will be mounted close to the crankshaft, usually at the rear or side of the engine block, near the starter. You can disconnect the starter and get to the sensor from under the truck with the right tools, good directions, and a little elbow grease. In some cases, you may need to remove one of the front wheels and the wheel well covering to reach the starter.

Safety Tip: You're dealing with electricity when removing the starter, so it's critical to disconnect the negative battery terminals on both batteries in your truck before starting the replacement process.

4. EGR (Exhaust Gas Recirculation) Valves

EGR valves were introduced in the 1970s to reduce the number of pollutants released into the air through the exhaust, namely carbon monoxide, hydrocarbons, particulate matter, and nitrogen oxides. In diesel engines, the EGR valve recirculates the exhaust back through the intake manifold and into the combustion chamber. This process cools the combustion chamber with the recirculated exhaust, and as a result, the engine performs more efficiently and emits lower levels of harmful nitrogen oxides into the air.

Over time, carbon particles, soot, and fuel deposits may accumulate in the valve and cause it to malfunction. The valve has a bad reputation for failing and destroying more expensive engine components, like turbochargers, so paying close attention to maintenance is critical.

Signs that your valve might be failing include rough idling, poor acceleration, and low fuel efficiency. While you can continue to drive with a faulty EGR valve, you do so at the risk of incurring more serious - and more expensive - issues. At the very least, your truck won't pass an emissions test, which will delay renewing your registration.

The EGR valve is easily accessible under the hood between the intake manifold and exhaust manifold, and you'll probably only need a few wrenches and a screwdriver to remove it.

5. Belts, Hoses, Fuses, and Bearings

These parts can often crack, break, or blow, leaving you without essential functions like working headlights or proper engine airflow. For example, a cracked air hose could lead to engine misfires and increased carbon deposits from unfiltered air. A break in your cam belt can throw off your engine timing and cause pistons and valves to collide, seriously damaging your engine. Or a failing bearing can lower your oil pressure and cause engine knocking and other destructive issues.

By keeping these smaller parts on hand and regularly checking your engine for wear and tear, you can quickly pinpoint potential trouble spots. Whether you replace them or have a trained repair person do the work, having readily available parts will help you address the damage immediately.

Also remember to store a healthy supply of coolant, diesel injection cleaner, and quality oil to match your season, e.g., a lower-viscosity oil for colder winter months. Your trucks will quickly get back to business without breaking the bank by being prepared with the correct replacement parts and fluids.

Infographic

Since winter has arrived, it's more important than ever to keep your trucks working in all conditions. Sadly, all that lovely snow and ice may cause havoc on your diesel engines. How do you maintain your fleet operating? Our professionals advise that you always maintain the following replacement parts on hand as a seasoned diesel parts supplier.